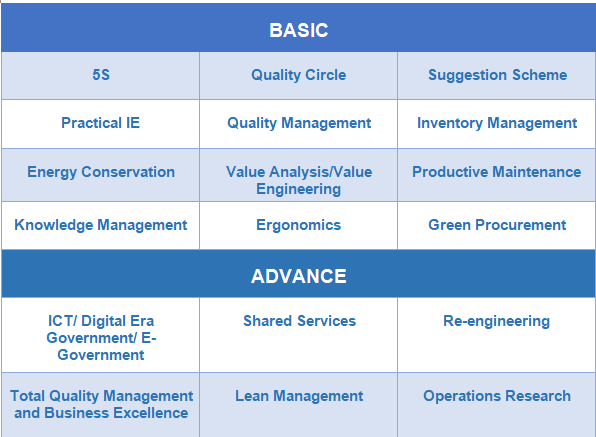

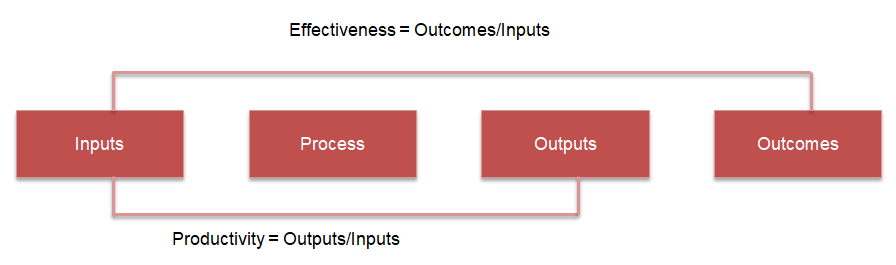

A productivity specialist always strives to achieve high productivity and quality. To be able to do this, he/she must have the knowledge and competencies in different productivity and quality (P&Q) tools which will help in improving the effectiveness and efficiency of an organization. P&Q tools are grouped into two major groups – basic and advanced. Basic tools help an organization to identify procedures, ideas, cause and effect, and other issues relevant in improving its performance, while advanced tools involves more complex processes such as measurement techniques, statistical data analysis, lean concepts, and the business excellence frameworks.

Basic

- 5S – A systematized approach to organize work areas, keep rules and standards, and maintain discipline. It utilizes workplace organization and work simplification techniques.

-

- Seiri (Sort) – Take out unnecessary items and dispose

- Seiton (Sytematize) – Arrange necessary items in good order

- Seiso (Sweep) – Clean your workplace

- Seiketsu (Sanitize) – Maintain high standard of housekeeping

- Shitsuke (Self-discipline) – Do things without being told or ordered

- Quality Circle– involves a small group of employees from the same workplace organized to identify problems and suggest solutions to work-related issues. A quality circle, also known as Work Improvement Team, Synergy Team, and Support Team, has seven basic features: voluntary in nature; small in size; homogenous in membership; projects within control; systematic and scientific in approach, continuing in activity and universal in application.

- Suggestion Scheme – A systematic approach to solicit innovative ideas for improvement. It promotes two-way communication between management and employees wherein good ideas are recognized and rewarded to encourage active participation. However, grievance, bargaining and policy issues are not part of the themes for suggestions.

- Practical IE – offers simple but systematic techniques to analyze operations, processes and integrated systems with a view to improving efficiency, effectiveness and economy, and makes inefficiencies visible. Among the practical IE techniques are:

- Method study – systematic examination of doing work in order to develop and apply easier and more effective methods and reduce costs

- Work measurement – used to obtain time data for method study and establish standard time to perform tasks

- Quality Management – An approach to ensure that the desired quality of a good or service is delivered. It covers quality planning, quality assurance, quality control and quality improvement. ISO 9000 standards provide guidelines on how to establish QM systems.

- Inventory Management – Approach to oversee and control the ordering, storage and use of supplies, materials, components and other items that the organization will use for the production of goods and services.

- Energy Conservation – Reducing energy consumption through using less of an energy service.

- Value Analysis/Value Engineering – An approach to improve the value of an item or process by first understanding the functions of the item and their value, then by identifying its constituent components and their associated costs. It then seeks to find improvements to the components by either reducing their cost or increasing the value of their functions.

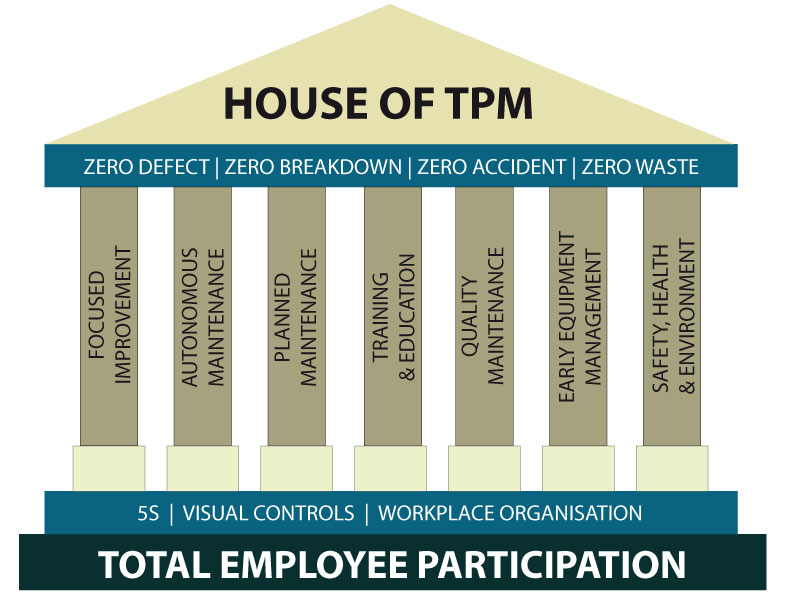

- Productive Maintenance – A maintenance management approach that looks at maintenance as a productive function, and considers that it should be the concern of every unit in the organization. It aims to eliminate big losses on equipment effectiveness e.g. setup time, breakdown, speed losses, waiting time, etc. All levels in the organization must cooperate in ensuring the productive functioning of equipment and physical facilities.

- Knowledge Management – An integrated approach of creating, sharing, and applying knowledge to enhance productivity, profitability and growth.

- Ergonomics – Making better use of human capacities (economize motions) and protect workers from hazards and other poor work conditions that negatively affect worker’s occupation health and productivity. Principles: – Safety – Comfort – Ease of use – Productivity – Aesthetics

- Green Procurement- Purchasing products and services that cause minimal adverse environmental impacts. It incorporates human health and environmental concerns into the search for high quality products and services at competitive prices.

Advanced

- ICT/ Digital Era Government/ E-Government – Involves the use of computer technology and conversion of manual records into computer files to automate data and transaction processing thus minimizing or removing manual work and intervention that is susceptible to corruption

- Shared Services – A strategy to “move out†major support processes out of individual units by “concentrating them†in order to improve cost efficiencies, service levels, and responsiveness.

- Re-engineering –Strategic review, analysis, and redesign of structure, workflows, and processes to achieve higher efficiency, effectiveness and economy.

- Total Quality Management and Business Excellence – A managerial approach centered on quality based on participation of all members and aimed at continually improving performance over the long term by focusing on customers while addressing the needs of all stakeholders.

- Lean Management – A management philosophy that seeks to maximize value to customers, both internal and external while simultaneously removing wasteful activities and practices.

- Operations Research – Employing scientific and mathematical techniques to determine optimal or near-optimal solutions to complex decision making:

-

- Mathematical optimization

- Queuing studies

- Simulation

- Econometric analysis

- Data envelopmental analysis